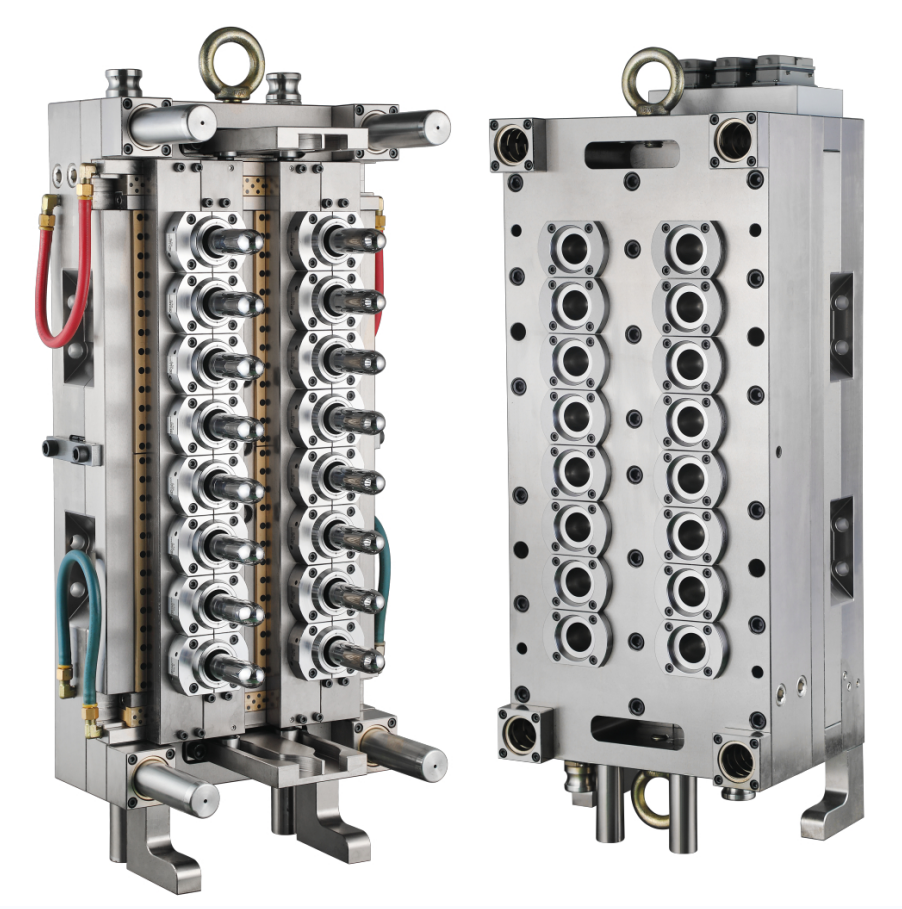

Before the mold is delivered, it is necessary to test the mold, check the quality of the mold, and improve the product quality of the mold. What should you pay attention to in the process of testing the mold?

1. At the beginning of injection molding, it is not allowed to fill the cavity immediately, and the injection molding amount should be gradually increased.

2. Adjust the relevant equipment and injection molding process parameters according to the actual condition of the product during injection molding.

3. The upper socket of the mold and the heater in the mold should not come into contact with water, otherwise it will cause damage to the heater and temperature control box parts in the mold.

4.When the preform mold is heated, open the main channel temperature first, and when the main channel temperature rises to the set value, the diverter channel switch can be turned on to avoid the raw material decomposition and blackening caused by premature heating of the diverter channel.

5.Set the relevant equipment and process parameters, and open the mold according to the mold action sequence after reaching the set value.

6. According to the action sequence of the preform mold, test the mold action repeatedly with no load, check whether the mold valve needle opening and closing are synchronized, and whether the slider system is smooth and in place.

7. Do not warm the mold without cooling water. High temperature may cause damage and deformation of mold parts and seals.

8. Connect water, gas, electricity and hydraulic pipes according to the requirements of preform injection molding machine and mold.

Everyone should pay attention to the above 8 items in the process of trying the mold to prevent accidents.

Post time: Sep-26-2023