Products

-

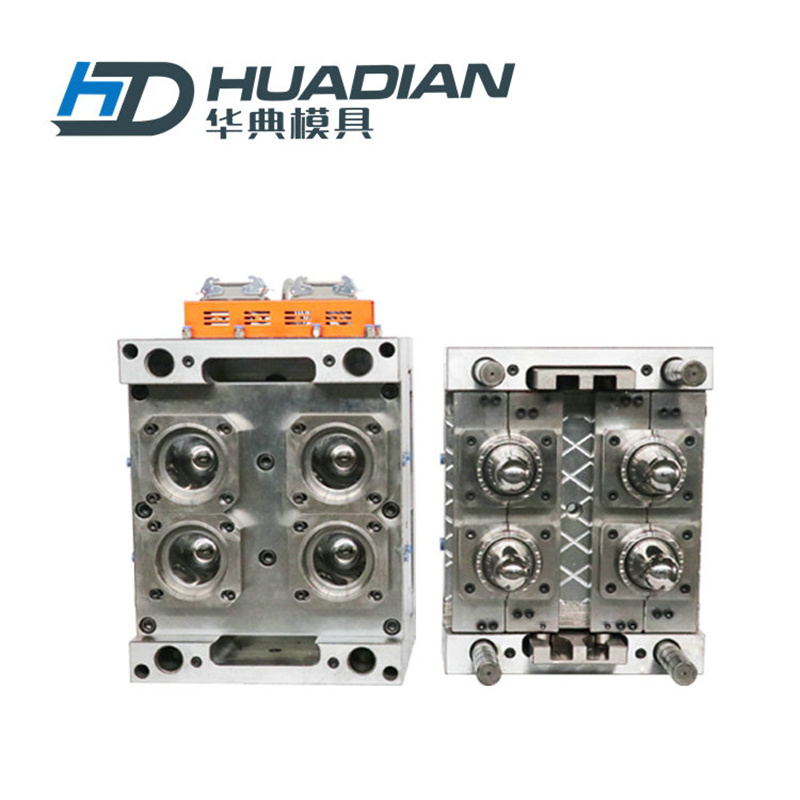

8 Cavities Jar PET Preform Mould

Name:8 Cavities Perform Mould Country of Origin:Taizhou, Zhejiang, China Brand:HUADIAN Cavity:8(4*2) Material of bottle:PET Material of Mold:P20 Material of Mold core, cavity, screw opening:S136 Software:CAD, PRO-E, UG Runner:Hot Runner Mold Components:all from World-famous manufactures, Insulation Caps from American DOPONT, Band Heater from Germany HOSTET, Copper Nozzl from Italy… Jar Size NECK: 60.5mm 70mm 70mm 86mm 86mm 110mm 70mm 86mm 63mm 120mm 97mm 86mm 120mm 120mm 120mm 122mm... -

8 Cavities Oil Bottle PET Preform Mold

- Name:8Cavities Oil bottle Perform Mould

- Country of Origin:Taizhou, Zhejiang, China

- Brand:HUADIAN

- Cavity:8(4*2)

- Material of bottle:PET

- Material of Mold:P20

- Material of Mold core, cavity, screw opening:S136

- Software:CAD, PRO-E, UG

- Runner:Hot Runner

- Mold Components:all from World-famous manufactures, Insulation Caps from American DOPONT, Band Heater from Germany HOSTET, Copper Nozzl from Italy…

The Advantage On Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiencyKey Performance Of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.Mold Data8 Cavities Oil Bottle PET Perform Mold is a high-quality, high-efficiency PET bottle mold suitable for the production of bottled edible oil. With 8 cavities, the volume is suitable for the production of PET products such as bottled edible oil. The hot runner operation mechanism is adopted to reduce PET waste and improve production efficiency. At the same time, it can effectively control the temperature and improve the quality of the produced products.

8 Cavities Oil Bottle PET Perform Mold is made of high-quality P20 mold material, and the mold core, cavity, and screw opening are made of imported S136 material, which ensures the durability and high strength of the mold. The biggest feature of this mold is that it has 8 cavities, and the volume is suitable for the production of PET products such as bottled edible oil. The manufacturer can customize the production according to the specific needs of customers.

The mold adopts a hot runner operation mechanism. The hot runner uses different materials and temperatures, and controls the independent temperature of each injection point to ensure the uniformity of the PET material during filling, injection and cooling. These characteristics can not only improve the manufacturing strength of the product, but also prolong the service life of the mold. At the same time, the mold helps reduce production costs and increase production efficiency due to reduced PET waste.

This mold is very suitable for producing bottled edible oil and other PET products. Compared with other PET products, this mold can also be widely used in beverage bottles, condiment bottles and other fields. Using this mold, manufacturers can produce PET products more quickly and efficiently, while improving product quality and production efficiency. In addition, the mold is equipped with a temperature control box and an operator, which is convenient to control the production process and easy to use.

In summary, 8 Cavities Oil Bottle PET Perform Mold is a high-quality, high-efficiency PET bottle mold with custom production features, suitable for developing the market for bottled edible oil and other PET products. Its high quality, high efficiency, wide applicability and reduced PET waste make it an ideal choice for manufacturers to reduce production costs, improve production efficiency and optimize product manufacturing.

-

8 Cavities Oil bottle PET Perform Mold

Specifications 0il Bottle Size 1L-2.5L 1.8L- 2.5L 10L 20L Neck 32MM, 37MM, 46M, 46MM 62MM, 72MK 0il Bottle Eight 20G, 25G, 28G, 30G, 35G, 40G, 40G, 43G 50G, 55C, 600, 63G, 65C. 680, 700, 756, 77G, 82G 85G, 90G, 93G, 95G, 100G, 120G, 140G, 145G, 150G 175C, 230C, 245G, 250G The advantage on Hot Runner Technique 1. Reduce the wastage and cost of raw materials. 2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work effic... -

16 Cavities Oil bottle Hot runner Perform Mold

Specifications 0il Bottle Size 1L-2.5L 1.8L- 2.5L 10L 20L Neck 32MM, 37MM, 46M, 46MM 62MM, 72MK 0il Bottle Eight 20G, 25G, 28G, 30G, 35G, 40G, 40G, 43G 50G, 55C, 600, 63G, 65C. 680, 700, 756, 77G, 82G 85G, 90G, 93G, 95G, 100G, 120G, 140G, 145G, 150G 175C, 230C, 245G, 250G The advantage on Hot Runner Technique 1. Reduce the wastage and cost of raw materials. 2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work effic... -

4 Cavities Jar PET Perform Mold

Jar Size NECK: 60.5mm 70mm 70mm 86mm 86mm 110mm 70mm 86mm 63mm 120mm 97mm 86mm 120mm 120mm 120mm 122mm 120mm 148mm 62mm 71.5mm 71.5mm 71.5mm 71.5mm Weight: 30g 35g 43g 43g 52g 52g 53g 65g 65g 85g 88g 90g 95g 100g 120g 160g 170g 193g 150g 175g 250g 270g 290g The advantage on Hot Runner Technique 1. Reduce the wastage and cost of raw materials. 2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space. 3.Avoid to use... -

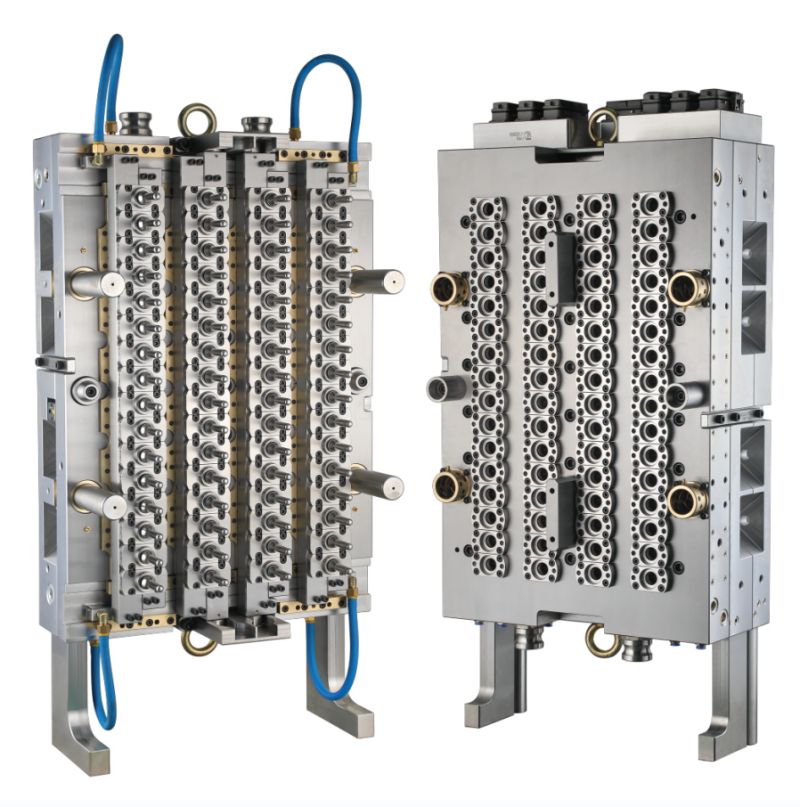

72 cavities water bottle preform large mold

The Advantage On Hot Runner Technique 1. Reduce the wastage and cost of raw materials. 2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space. 3.Avoid to use the returned materials which will influence the quality of product. 4.Guarantee the product in the same quality level 5.Increase the injection volum,Improve the compressibiity of plastic melt 6.Intesify the injection function, improve the technique 7.Reduce the time... -

Multi-cavity daily cosmetics bottle preform mould

We are excited to launch our breakthrough product – Cosmetic Bottle Preform Molds. Combining the latest innovations in mold technology with our company’s exceptional attention to detail and commitment to customer satisfaction, this mold is sure to revolutionize the cosmetics industry. With its cost-effective design, high precision and unparalleled efficiency, our molds will improve the production processes of cosmetic bottle manufacturers worldwide.

-

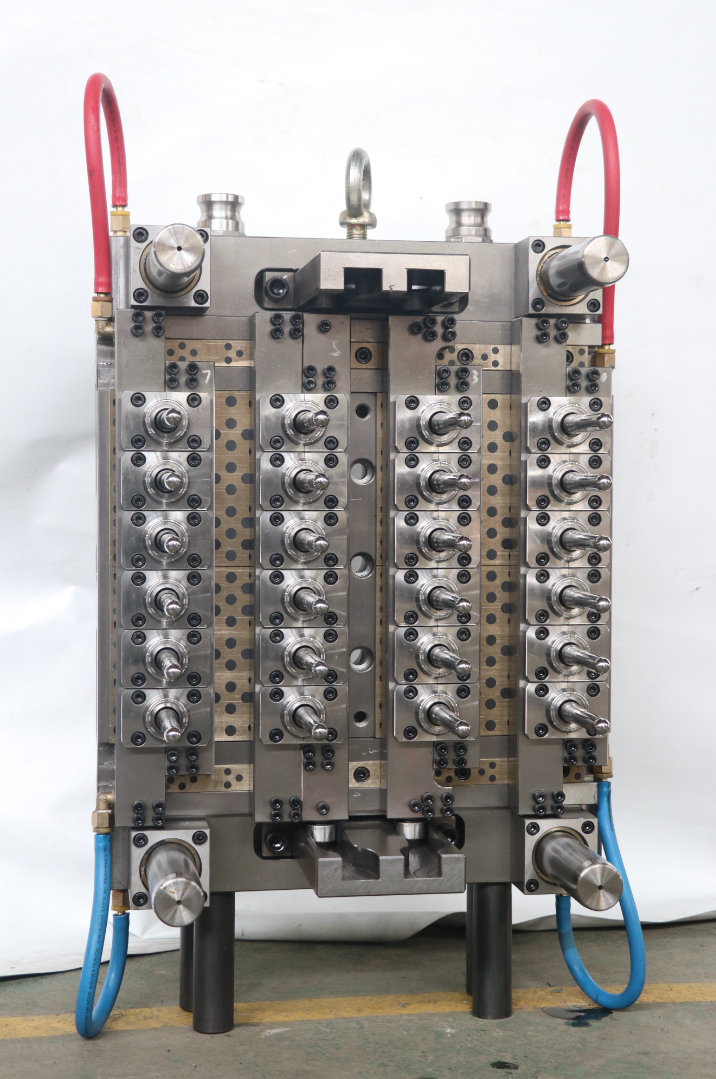

32 cavities hand sanitizer air-sealed preform mold

Mold Components:all from World-famous manufactures, Insulation Caps from American DOPONT, Band Heater from Germany HOSTET, Copper Nozzl from Italy…

-

6 Cavities Jar Air Sealed needle vavle Perform Mold

- Name:6 Cavities Perform Mould

- Country of Origin:Taizhou, Zhejiang, China

- Brand:HUADIAN

- Cavity:6(2*3)

- Material of bottle:PET

- Material of Mold:P20

- Material of Mold core, cavity, screw opening:S136

- Software:CAD, PRO-E, UG

- Runner:Hot Runner

- Mold Components:all from World-famous manufactures, Insulation Caps from American DOPONT, Band Heater from Germany HOSTET, Copper Nozzl from Italy…

-

48 Cavities Air-Sealed PET Preform Mold With Manipulator

- Name:48 Cavities Air Sealed Perform Mould

- Country of Origin:Taizhou ,Zhejiang,China

- Brand:HUADIAN

- Cavity:48(4*12)

- Material of bottle:PET

- Material of Mold:P20

- Material of Mold core, cavity,screw opening:S136

- Software:CAD, PRO-E, UG

- Runner:Hot Runner

- Mold Components:all from World-famous manufactures, Insulation Caps from American DOPONT, Band Heater from Germany HOSTET, Copper Nozzl from Italy..

-

Launched 24-cavity self-locking common bottle preform mold

With years of production experience and a commitment to operating with integrity and quality first, we are pleased to present to you our latest innovation in the field of PET preform molds – 24-cavity self-locking universal preform mold. The mold’s combination of thermal stability, durability and user-friendly design will revolutionize the preform production process.

-

48 Cavities Air seal Perform Mold with temperature control box and manipulator

Specifications Cavity Perform Mold Size Mold Weight Cycle Time Weight(g) Neck(mm) Height(mm) Width(mm)) Thickness(mm) (kg) (sec) 2(1*2) 720 55 470 300 608 330 125 4(2*2) 720 55 490 480 730 440 130 8(2*4) 16 28 450 350 410 475 18 12(2*6) 16 28 600 350 415 625 18 16(2*8) 21 28 730 380 445 690 22 24(3*8) 28 28 770 460 457 1070 28 32(4*8) 36 28 810 590 515 1590 28 48(4*12) 36 28 1070 590 535 2286 30 The advantage on Hot Runner Technique 1. Reduce the wa...