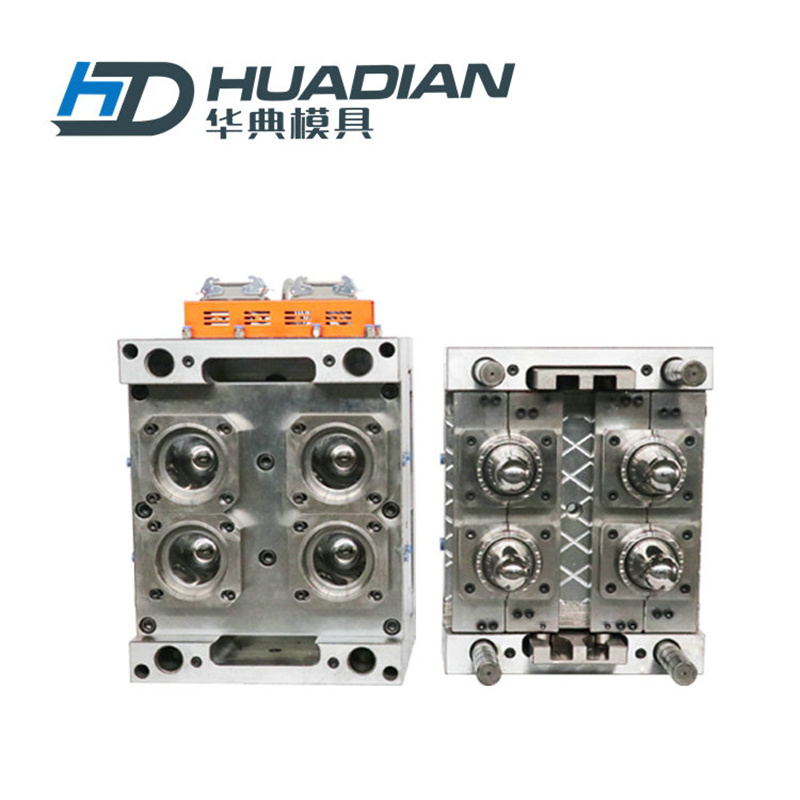

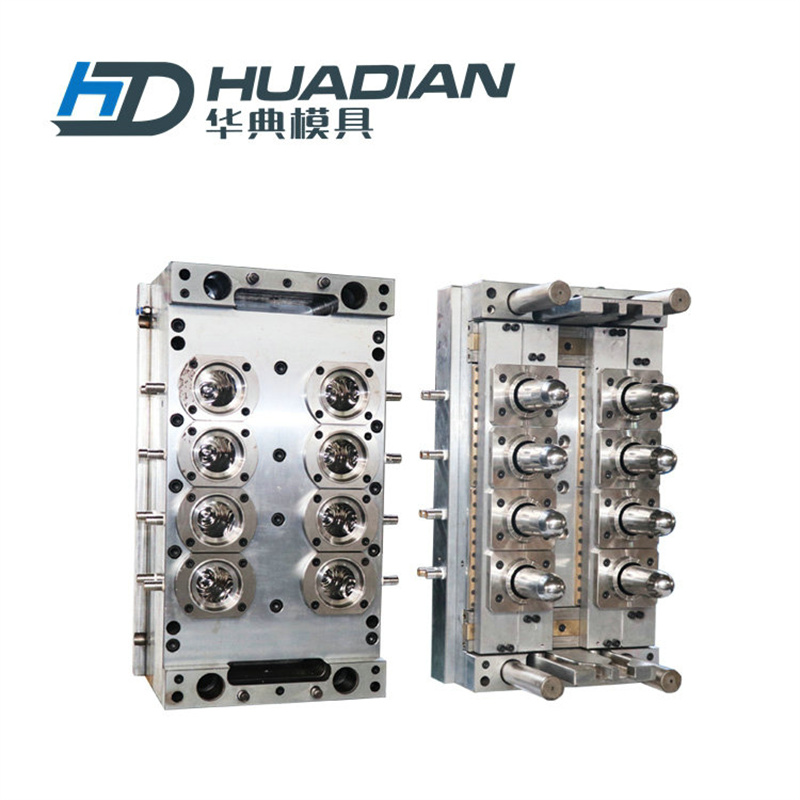

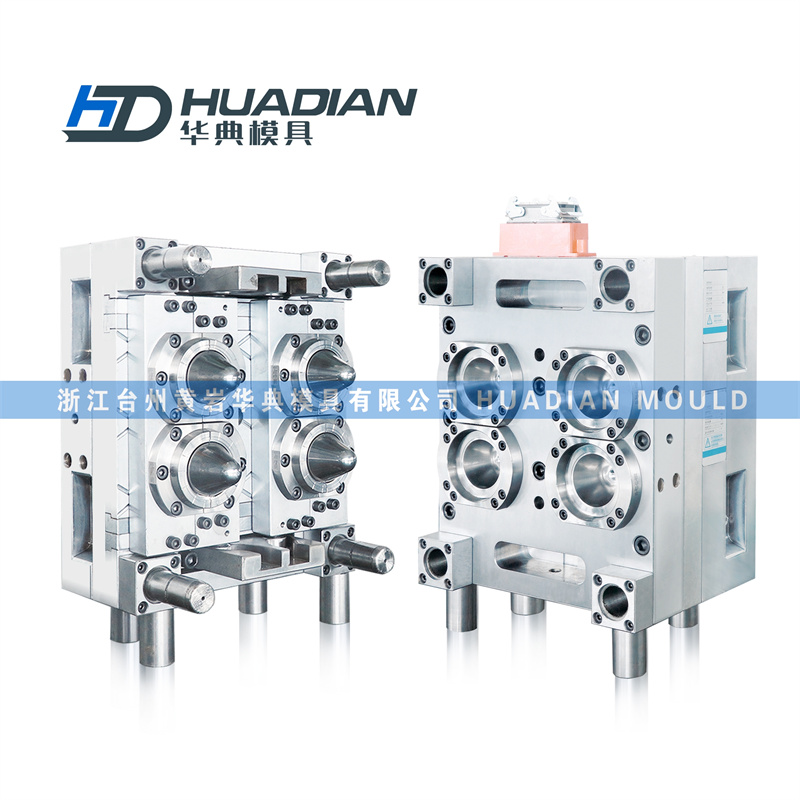

4 Cavities Jar PET Perform Mold

Jar Size

- NECK: 60.5mm 70mm 70mm 86mm 86mm 110mm 70mm 86mm 63mm 120mm 97mm 86mm 120mm 120mm 120mm 122mm 120mm 148mm 62mm 71.5mm 71.5mm 71.5mm 71.5mm

- Weight: 30g 35g 43g 43g 52g 52g 53g 65g 65g 85g 88g 90g 95g 100g 120g 160g 170g 193g 150g 175g 250g 270g 290g

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

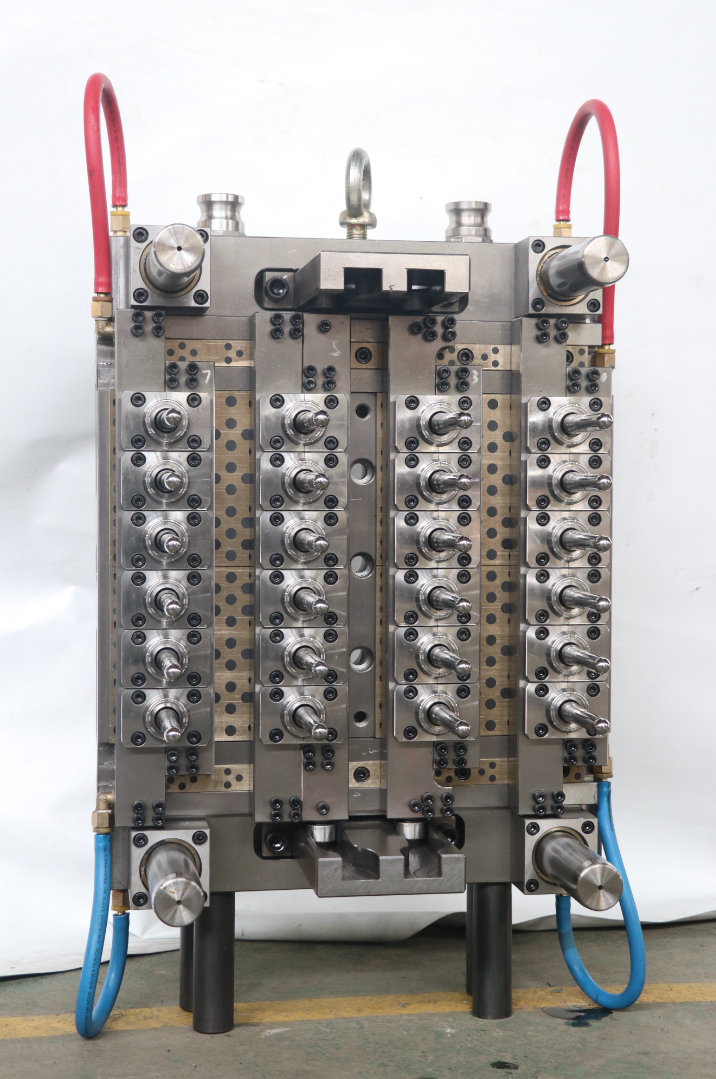

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

HUADIAN's 4-cavity air-sealed Perform Mold is a high-efficiency, high-quality PET bottle mold. Due to the separate design of the hot runner, the quality of filling and injection is greatly improved, and at the same time, the temperature of each cavity can be better controlled and the waste of PET materials can be reduced to save production costs. This mold is suitable for the production needs of pet bottles, and can be widely used in cosmetics, disinfectants and other fields.

HUADIAN's 4-cavity air-sealed Perform Mold uses high-quality P20 mold material, which improves the strength and durability of the mold. The mold core, cavity and screw opening are made of imported S136 material to ensure product accuracy and mold life. The size of each cavity of the mold is 2*2, with a total of 4 cavities, which can meet the production needs of PET pet bottles.

The mold adopts hot runner separation design to ensure that the injection temperature of each cavity can be controlled independently, which greatly improves the quality of filling and injection, thereby reducing production waste and improving production efficiency. The mold is also equipped with a temperature control box and an operator, which are easy to use, convenient to control the production process, and reduce production costs. These characteristics make HUADIAN's 4-cavity air-sealed Perform Mold a better choice for manufacturers to reduce production costs, improve production efficiency and optimize product manufacturing.

Applicable fields include the manufacture of PET bottles, cosmetics and disinfectants. Using this mold, manufacturers can produce PET bottles more quickly and efficiently, which are widely used in various fields and meet customers' demand for high-quality and high-efficiency products.

In conclusion, HUADIAN's 4-cavity air-sealed Perform Mold is a high-quality, high-efficiency PET bottle mold with multiple advantages and applications, which can improve the manufacturer's production efficiency, reduce production costs, optimize product manufacturing, and improve product quality. quality. If you are a PET bottle manufacturer, or need to produce PET products, this mold will be your indispensable choice.