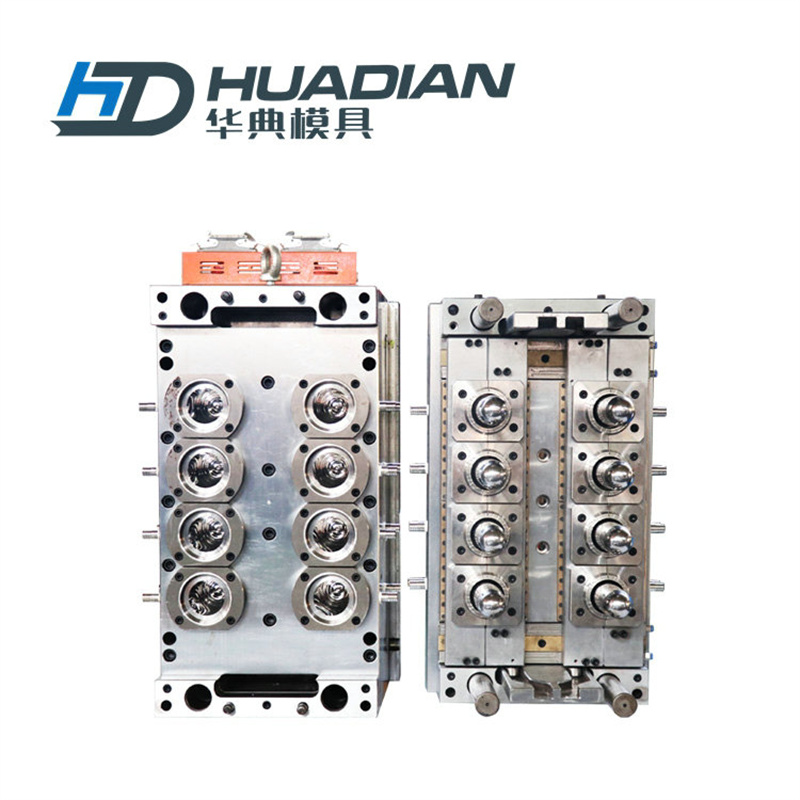

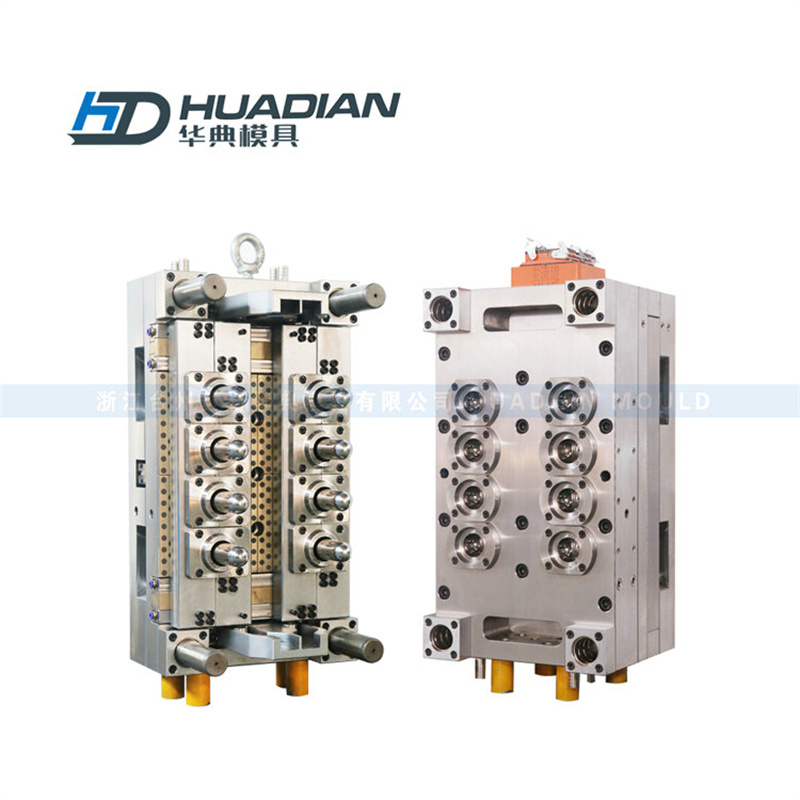

8 Cavities Oil bottle Air Sealed Perform Mold

Specifications

| 0il Bottle Size | 1L-2.5L | ||||||

| 1.8L- 2.5L | |||||||

| 10L | |||||||

| 20L | |||||||

| Neck | 32MM, 37MM, 46M, 46MM | ||||||

| 62MM, 72MK | |||||||

| 0il Bottle Eight | 20G, 25G, 28G, 30G, 35G, 40G, 40G, 43G | ||||||

| 50G, 55C, 600, 63G, 65C. 680, 700, 756, 77G, 82G | |||||||

| 85G, 90G, 93G, 95G, 100G, 120G, 140G, 145G, 150G | |||||||

| 175C, 230C, 245G, 250G | |||||||

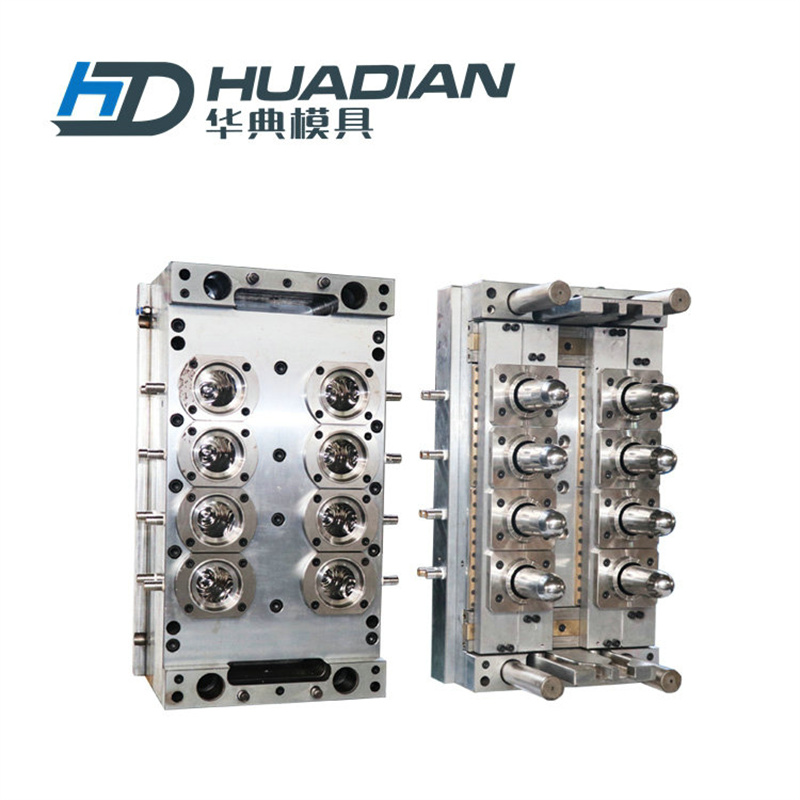

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

mold data

| Name | Pet Oil Bottl Perform Mold |

| Cavity And Core | S136(8, 12, 24, 48, 96HRC) |

| Mold Shelf | P20 |

| Cavity Qty | As Customi Zed |

| product Standard | Lkm, Dme, Hasco |

| Rotary Wheel Type | Hot Board |

| Cycle Time | Short |

| Software | UG, PROE, CAD |

| Perform Material | Pet |

| Perform SiZe | As Customi Zed |

| Working Life | 3-4Million |

| Delivery Time | 45-50DaysAYS |

Product application:

The mold is suitable for the production of various sizes and shapes of oil bottles, including automotive oil bottles, cosmetics oil bottles, and various other types of oil bottles, which can help manufacturers reduce costs and improve efficiency, so as to better meet the market demand.

Product installation:

The mold is flexible in design and easy to operate, and can be easily installed into the equipment. And ensure that it works properly and gets the best results by installing and operating according to the instructions.

8 Weathered Oil bottle Air Sealed Perform Mold is a high efficiency, high performance, high toughness mold. It can not only help manufacturers improve production efficiency and reduce costs, but also provide high-quality oil bottles, thus maintaining market share in a highly competitive market. Both in use, maintenance and maintenance, this mold is very practical, easy to use and reliable, so it will become an indispensable auxiliary tool for all types of oil bottle manufacturers.