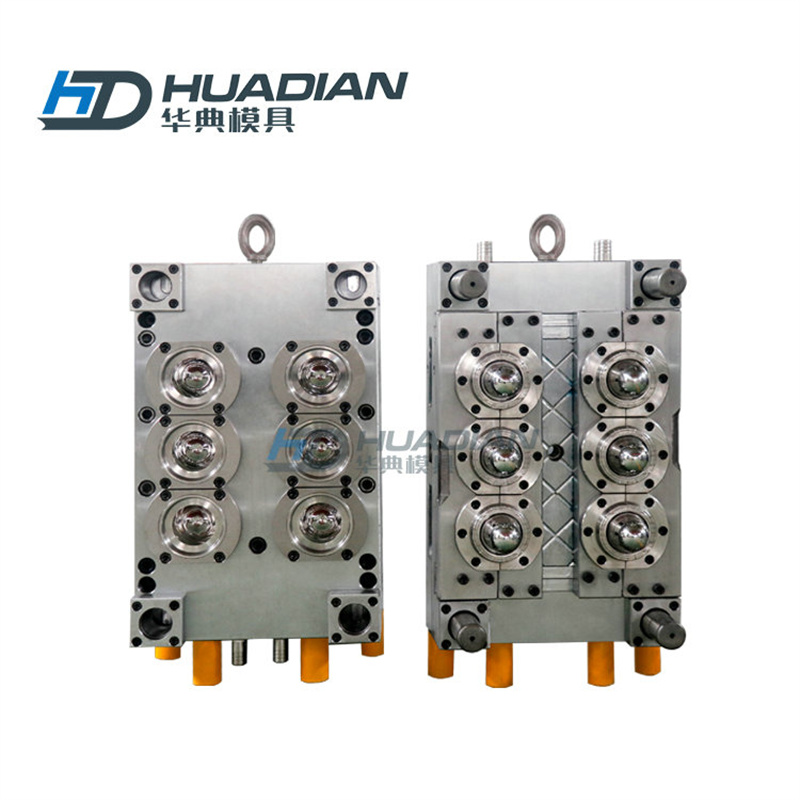

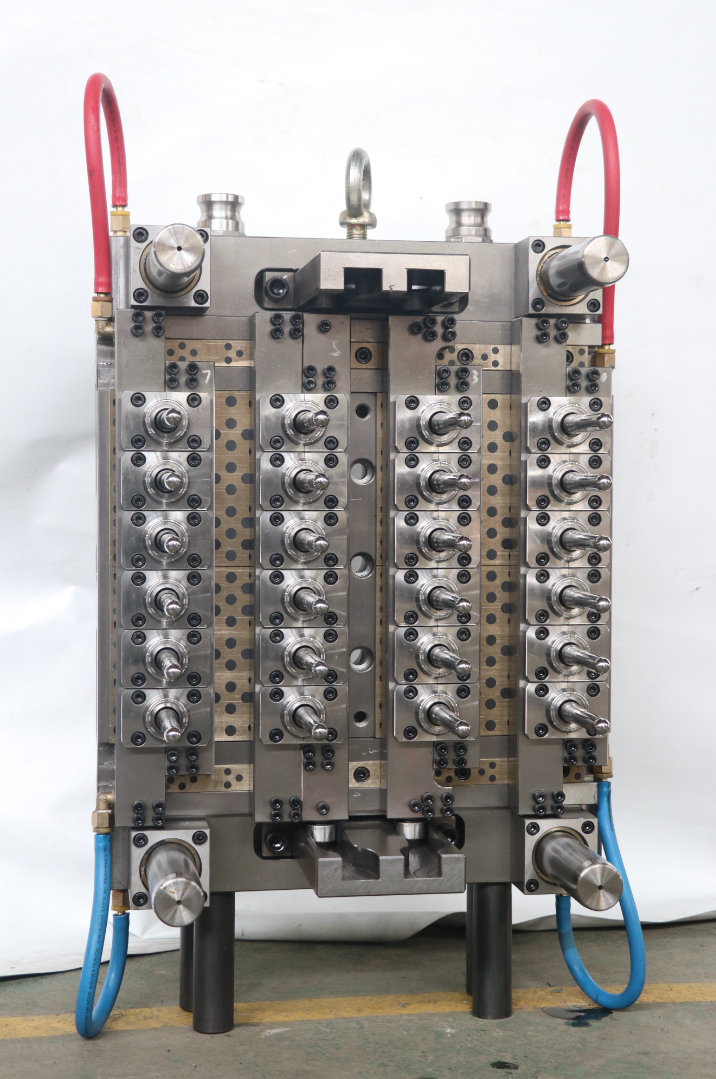

12 Cavities once forming CAN Preform Mould

Specifications

| 0il Bottle Size | 1L-2.5L |

| 1.8L- 2.5L | |

| 10L | |

| 20L | |

| Neck | 32MM, 37MM, 46M, 46MM |

| 62MM, 72MK | |

| 0il Bottle Eight | 20G, 25G, 28G, 30G, 35G, 40G, 40G, 43G |

| 50G, 55C, 600, 63G, 65C. 680, 700, 756, 77G, 82G | |

| 85G, 90G, 93G, 95G, 100G, 120G, 140G, 145G, 150G | |

| 175C, 230C, 245G, 250G |

Product details

1. Once forming can injection mold, there are strict requirements in the process of forming parts, pouring system, guide parts, release mechanism, mold temperature adjustment system, exhaust system and so on.

2. We use hot runner gas seal bottle preform technology, in the molding process, pay attention to quality at the same time, improve production efficiency, a molding.

3. High gloss, high hardness, transparency, cleanliness and so on are superior.

4. At the same time, there is no burr flash, etc., one injection molding release is completed, which greatly improves the production efficiency of the enterprise.

5. This product is currently used in the market for the packaging of pecans, dates, nuts and other products, welcome new and old customers to come to consult.

The Advantage On Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

Product copy

Introducing our 12-cavity once forming CAN preform mold! The preforms produced by this special mold are widely used in various industries. What sets our mold apart is that it produces preforms with few problems, resulting in a seamless production process. With its thermal stability and durability, this mold guarantees excellent performance and consistent results every time.

Our 12-cavity once forming CAN preform molds are designed and manufactured to perfection. Its operation is very simple and suitable for both experienced operators and beginners. Our molds have short production times and high productivity, ensuring you maximize your output without compromising quality.

One of the outstanding features of our 12-cavity once forming CAN preform mold is its hot runner technology. This innovation significantly reduces material waste and improves overall molding cycles. Compared with traditional molds, our molds save raw materials, reduce waste, and improve product quality, giving you a competitive advantage in the market. In addition, the high requirements on the equipment ensure the accuracy and perfection of the preforms.

With our 12-cavity once-forming CAN preform molds, you can be assured of the highest quality product. We are confident in the performance and reliability of our molds. Its efficient production processes and superior functionality make it an important tool for businesses looking to optimize operations and deliver quality products to their customers.

Huadian Company is located in Huangyanyan, known as the hometown of molds. We have specialized in mold production for many years and our experience speaks for itself. We operate with integrity and always put quality first. Over the years, we have developed strong relationships with many new customers, while also maintaining long-term partnerships with loyal customers.

We are eager to work with you to provide the best solution for your mold needs. Our team of experts is dedicated to delivering exceptional molds that meet your specific requirements. With our 12-cavity once forming CAN preform molds, you can improve your production processes and take your products to new heights. Trust our experience, professionalism and commitment to quality and let us help you succeed in your industry. Contact us today and let us show you the possibilities our molds can bring to your business.