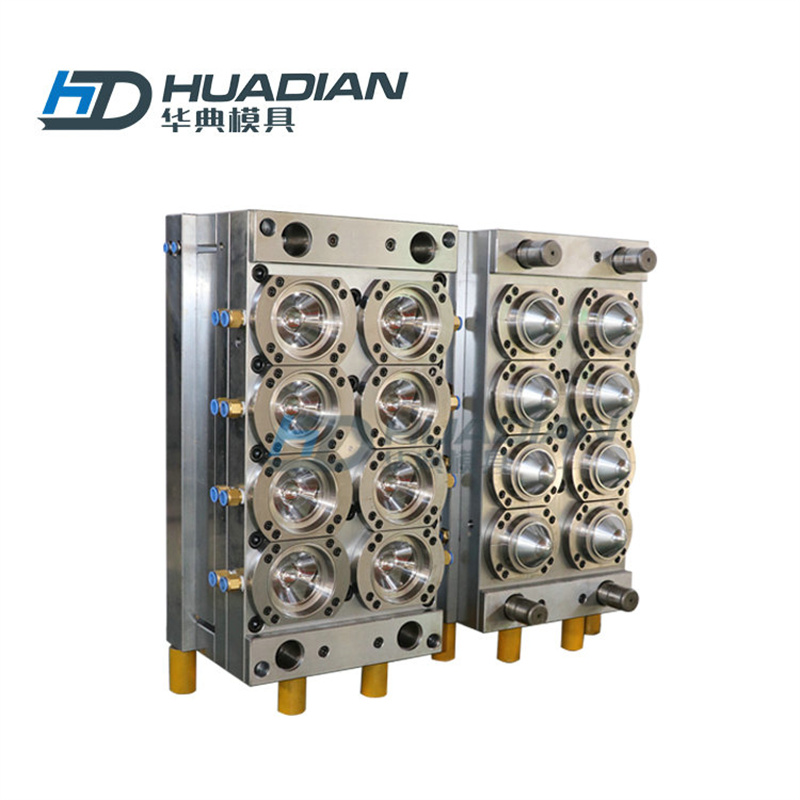

8 Cavities Jar PET Perform Mold

Jar Size

- NECK: 60.5mm 70mm 70mm 86mm 86mm 110mm 70mm 86mm 63mm 120mm 97mm 86mm 120mm 120mm 120mm 122mm 120mm 148mm 62mm 71.5mm 71.5mm 71.5mm 71.5mm

- Weight: 30g 35g 43g 43g 52g 52g 53g 65g 65g 85g 88g 90g 95g 100g 120g 160g 170g 193g 150g 175g 250g 270g 290g

The advantage on Hot Runner Technique

1. Reduce the wastage and cost of raw materials.

2. Reduce the work for recycle,classification,smash,dry,and store of waste, improve the work efficiency, save time and space.

3.Avoid to use the returned materials which will influence the quality of product.

4.Guarantee the product in the same quality level

5.Increase the injection volum,Improve the compressibiity of plastic melt

6.Intesify the injection function, improve the technique

7.Reduce the time of injection and pressure maintaining

8.Reduce Clamping force

9.Shorten Mold opening stroke of injection operation, Elimiate the time of taking out the Nozzle material

10.Shorten the injection cycle, improve the automation and work efficiency

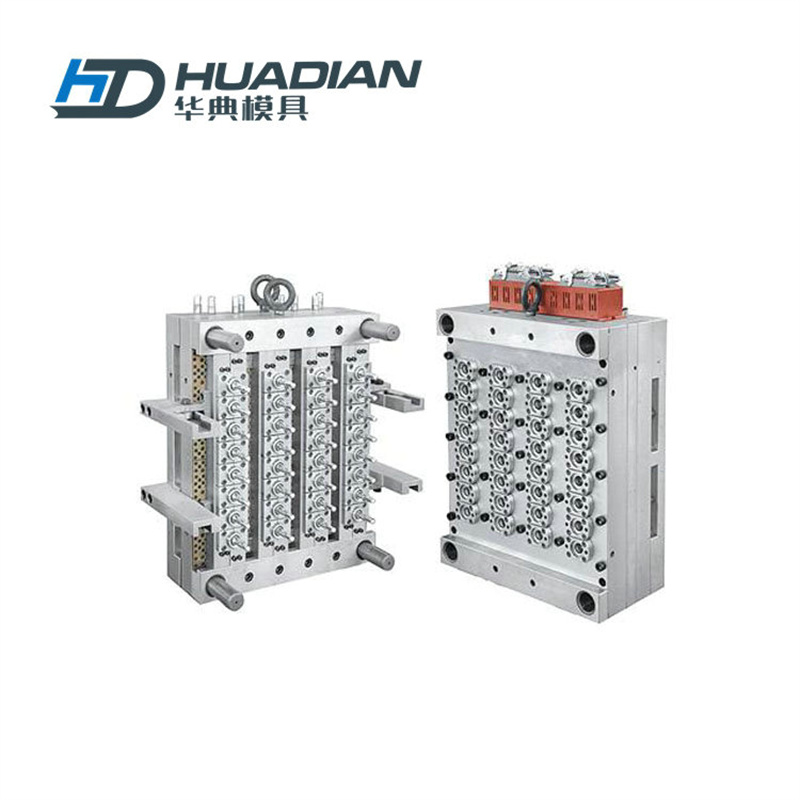

Key Performance of Hot Runner System

1.Control the temperature of plastic melt precisely, Elimiate the degration of materials.

2.Naturally balanced runner desgin, Mold Cavity evenly filled.

3.Suitable size of Hot Nozzle can be sure the plastic melt mobile successfully and mold cavity are filled evenly.

4.Correct gate structure and size can guarantee the mold cavity evenly filled,Needle valve gate closed in time, to shorten cycle time.

5. No dead angle in runner, insure to change the color quickly, avoid materials degration.

6. Mininize Pressure lose

7. Pressure maintaining time is reasonable.

The mold is made of high quality, high precision material processing, the design is unique, compact, the production process with computer precise control of temperature, to ensure that each precast has a high degree of accuracy, to achieve the best quality and efficiency.

In addition, the mold design has 8 independent cavity, accurate shape, excellent structure, can produce up to 8 prefabricated at the same time, and accurately control the size and shape of the prefabricated, to ensure that the maximum extent of the user's needs and requirements.

The mold is also characterized by its environmental protection, reducing the cost of using PET bottles and resource consumption, but also reduce the generation of waste and environmental pollution, in line with the environmental protection laws and regulations of various countries and regions.

This 8-cavity canned PET prefabricated mold also has many applications and installation, and can be widely used in food, cosmetics, medicine, daily necessities and other fields. Another excellent advantage of the mold is that each mold cavity is equipped with an independent hot runner system, which enables smooth melt forming. This leads to greater productivity, higher output and less waste.